Nishimura produce different types of Aluminum Nitride ceramics:

–ALN-170 is our standard Aluminum Nitride. (thermal conductivity: 170W/mK)

–ALN-200 is our Aluminum Nitride wit high thermal conductivity. (thermal conductivity: 200W/mK)

–ALN-230 Aluminum Nitride with highest thermal conductivity grade. (thermal conductivity:230W/mK)

–ALN-HY0 which has high purity(It doesn’t contain any auxiliaries). (thermal conductivity:90W/mK)

Pros

- ALN material has excellent thermal conductivity, heat radiation, and electric insulation.

- Significant thermal shock resistance.

- Thermal expansion goes well with a Silicon wafer.

- It has Good corrosion resistance to fluorine-containing gasses.

- Excellent plasma resistance.

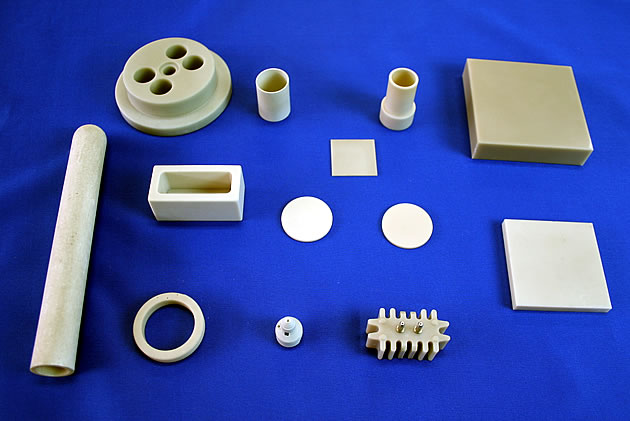

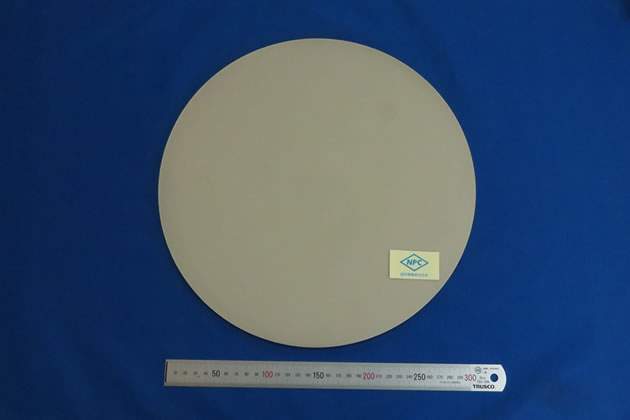

shape

- Plate, bar, pipe, crucible, complex design, We can produce in any shapes.

- Large size up to ∮600 is available.

Manufacturing

- Machine press, CIP, Green processing(Raw material machining)

Usage

- For heat sink, baseboard,soaking plate for the heater, crucible for OLED manufacturing, Aerospace industry, and parts of a semiconductor device.

| AlN material | Nishimura No. | |||

| Properties | AlN-170 | AlN-200 | AlN-HYO | |

| Thermal conductivity | W/mk(R・T) | 170 | 200 | 90 |

| Thermal emissivity | (100℃) | 0.93 | 0.93 | 0.93 |

| Thermal expansion coefficient | 10⁻⁶/℃(RT~400℃) | 4.5 | 4.5 | 4.5 |

| insulation resistane | Ω・cm(RT) | >10¹³ | >10¹³ | >10¹³ |

| Dielectric strength | kV/mm(RT) | 15 | 15 | 15 |

| Dielectric constant | (1MHz) | 8.8 | 8.8 | 8.8 |

| Dielectric loss | 10⁻⁴(1MHZ) | 5 | 5 | 5 |

| Fracture toughness | kgf/mm² | 35 | 40 | 40 |

| Bulk density | g/cm³ | 3.32 | 3.32 | 3.23 |

| Y | % | 3.5 | 3.3 | 0 |

| O | % | 1.5 | 1.2 | 0.58 |

| Metal inpurity | ppm | <500 | <500 | <500 |

| Feature | Standard use |

High thermal conductivity | High purity | |