|

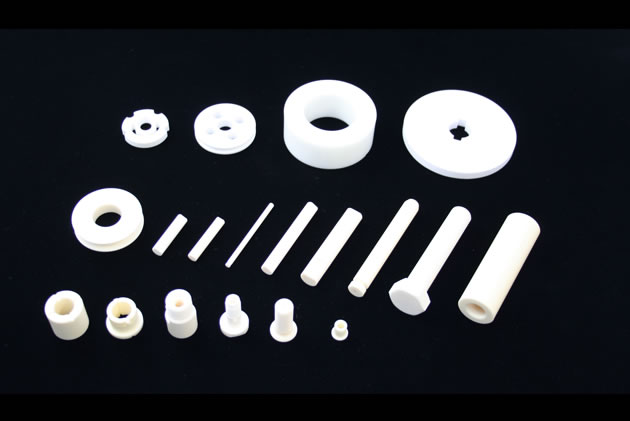

Ceramic products for machine parts and pump parts

Ceramic Parts Hong Kong propose the use of highly purified alumina ceramics for machine parts and pump parts.Highly pure alumina ceramics are extensively applied as an incredibly strong ceramic. It has excellent abrasion resistance, and there is no rival among other ceramic for its electrical insulation, chemical resistance and other abilities.

Alumina is applied to different purposes, utilizing its characteristics based on the percentage of its main ingredient, Al2O3.

With 92% purity, it has a more general purposes, usually used for metallization with high heat resistance.

With 96% purity, it is mostly applied to thick film substrate and for other purposes requiring mechanical strength.

With 99.7% or more purity, it has excellent heat conductivity, electrical insulation, abrasion resistance, chemical resistance, etc., and it is widely used since there is no other industrial materials as alernative.

Ceramic Parts Hong Kong’s alumina ceramics for machine parts and pump parts can reach 99.7% or more purity, thus as an edge-cutting technology, we can adjust the comprising of dense to achieve minor surface roughness.

Usage of alumina and others

Feature

Abrasion resistance, Chemical resistant and insulative

Processing

polishing and mirror polishing avaliable

|