Si3N4 Silicon nitride ceramics

Si3N4 is the only ceramics material with greater mechanical strength than Alumina or SiC and high thermal shock resistance. It is often applied for parts that require high mechanical strength in a high-temperature area.

Features

- High fracture toughness

- High mechanical strength in a high-temperature area.

- High thermal shock resistance. About 700℃

- Low thermal expansion 3×10⁻⁶/℃ (RT-800℃)

- Insulation property (over 10¹⁴Ωcm)

- High strength (800MPa)

- Lighter than Alumina or Zirconia.

- High corrosion resistance

- Quicker delivery than other companies

Application

- Parts that will be applied in a high-temperature area

- Parts that required high thermal shock resistance

- As a lighter version zirconia

Don’t hesitate to contact us anytime with your property requirements; we would like to select suitable ceramics material for you as a professional.

Showcase

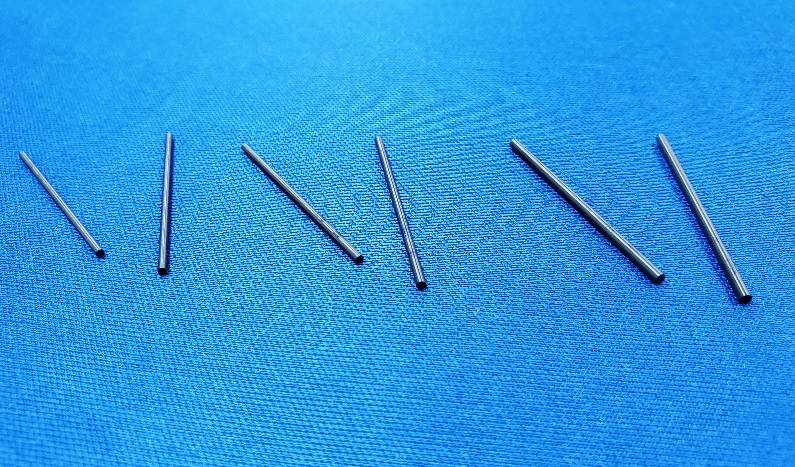

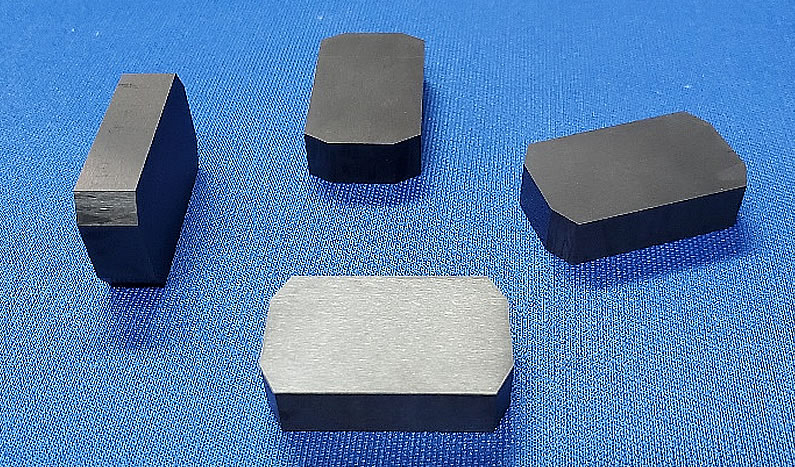

Si3N4 Silicon Nitride Ceramic (Pin, Shaft, Block)

|

|

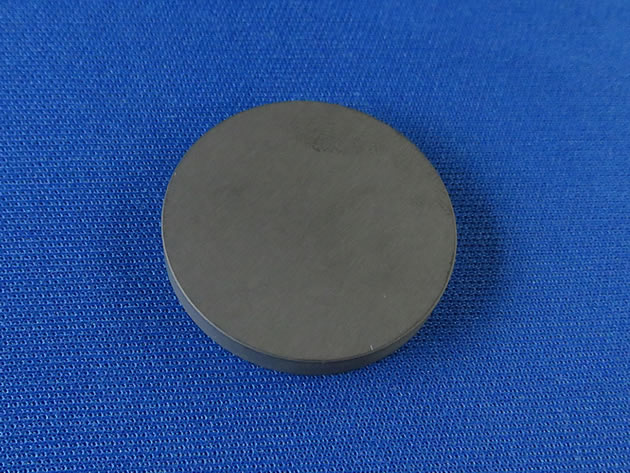

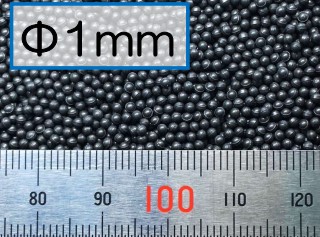

Silicon Nitride ball mill crushing ball

|

In the application of non-oxide ceramics pulverizing and glass frit pulverizing in the semiconductor field, our products have shown better performance in crushing effectiveness. Also, its wear resistance can reduce the mixing issues of Silicon Nitride. |

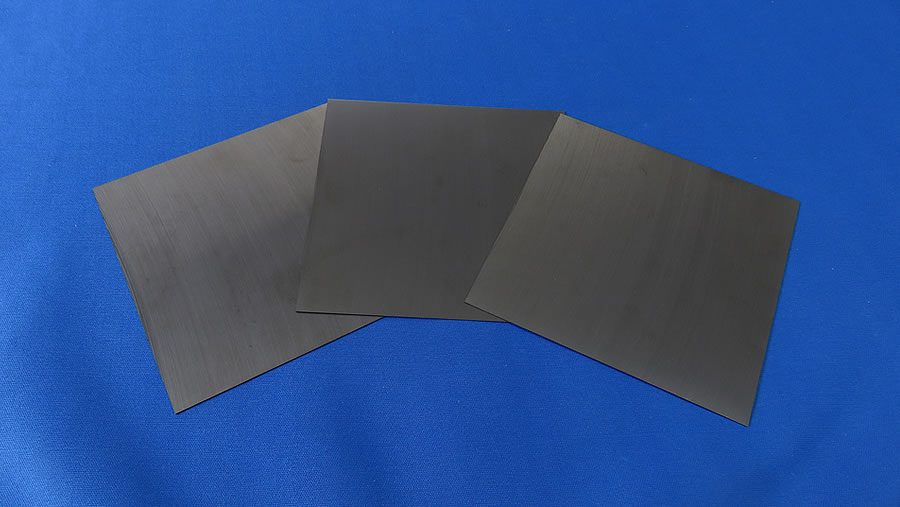

Si3N4 Silicon Nitride Ceramic substrate

SiC Silicon Carbide

SiC Silicon Carbide

SiC is a ceramics material with properties uniquely balanced compared to Alumina or Zirconia.

SiC is often applied for semiconductor manufacturing machine parts, pump parts, etc.

Features

- Sliding properties

- As high heat conductivity as Aluminum nitride (170w/mk)

- Smaller volume resistivity value than 10⁶Ωcm.

- High abrasion resistance(25GPa)

- High strength and high mechanical strength in high-temperature area

- Lighter than Zirconia or Alumina

- High corrosion resistance and great hardness.

Application

- Semiconductor manufacturing machine parts such as wafer arms.

- Shaft parts

- Frictional parts

Please contact us anytime with your property requirements; we would like to select suitable ceramics material for you as a ceramics professional.