Forsterite

|

MgO-Al2O3-SiO2 ceramics are composed of 2MgO-SiO2 (also called Mg2SiO4) forsterite crystals. |

Feature

|

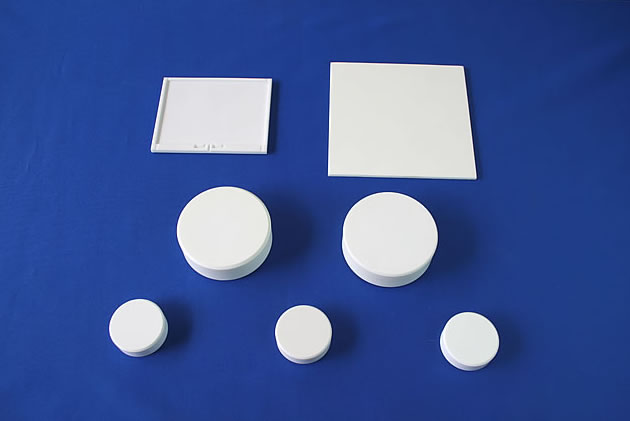

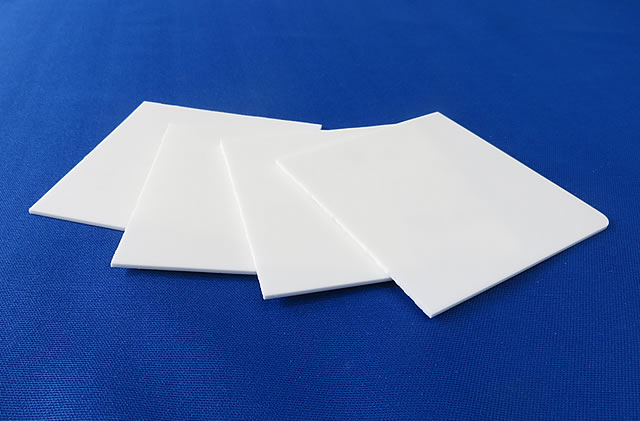

Forsterite is widely used as an electrically insulating material because of its light yellow appearance, smooth surface, and high strength. |

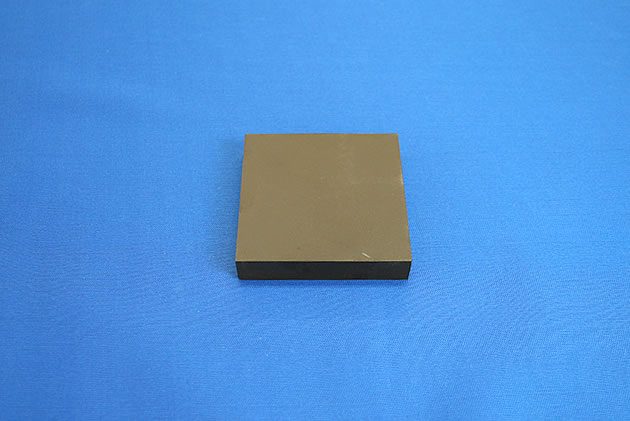

FB-10 Forsterite brown

|

A brownish-red ceramic mainly used for optical components, it has a coefficient of thermal expansion of 8.98 × 10-6/°C in the temperature range -30°C to 70°C. It has good bonding properties with glass. |

| Temperature Range | Thermal Expansion Coefficient |

| 30~600℃ | 11.1×10-6/℃ |

| -30~70℃ | 8.98×10-6/℃ |

Forsterite Characteristics

| Characteristics | Representative Value | Representative Value |

| Nishimura No. | N-75 | FB-10 |

| Main Component | 2MgO・SiO2 | 2MgO・SiO2 |

| Color | Pale Yellow | Dark Brown |

| Bulk Density | 3.0 | 3.2 |

| Water Absorption Rate | 0% | 0% |

| Bending Strength | 150MPa | 187MPa |

| Permittivity | 6.5(1MHz) | ― |

| Dielectric Tangent | 3×10-4(1MHz) | ― |

| Thermal Expansion Coefficient | 9.7×10-6/℃ | 11.1×10-6/℃ |

| Thermal Conductivity | 3.35 w/m・k | 5.9 w/m・k |

| Maximum Operating Temperature | 1000℃ | 1000℃ |