Apatite Bio ceramic APA-90

|

We have made apatite bio ceramic ball(diameter 10mm) by CIM, and confirmed performance of our Pearl core.(Patent No.2958579) |

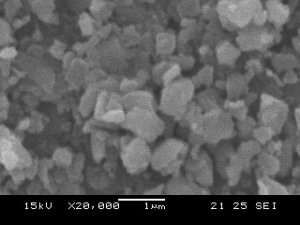

Sintered body

SEM picture(✕5000)

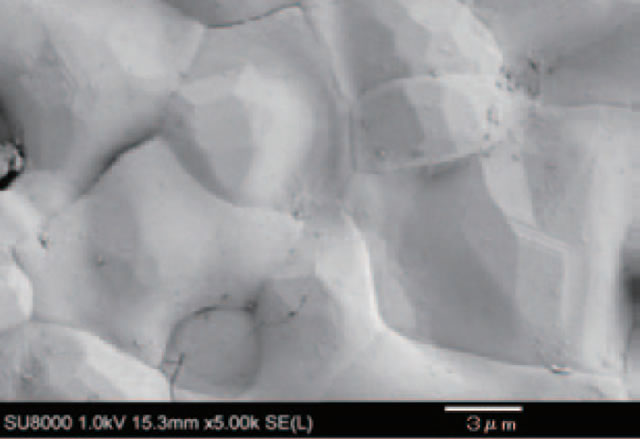

SEM picture(✕5000)

| Nishimura No. | APA-90 | |

| Main Component | Ca3(PO4)2 | |

| Bulk Density | g/cm3 | 2.77 |

| Bending Strenght | MPa | 30 |

(Reference:Bulk density of pearl is 2.65)

Application

Pearl core material(Patent No.2958579)

Based on our testing, we have checked the performance of this unique material.

This material is expected to be used as a alternative bone.

Nano Powder

Pulverized sintered apatite by bead mill and freeze-drying.

For it applies to cosmetic/ toothpaste/Quasi drag, We received a safety test by JFRL(Hong Kong Food Research Laboratories)

Safety Test

For apply to cosmetic/ toothpaste/Quasi drag, We took a safety test by JFRL(Hong Kong Food Research Laboratories)

| Subject | Researching Laboratories | Test Content | Test Result | Notes |

| Safety Test | JFRL |

Acute toxicity test (Rat,Both sexes) |

(LD50)>5000mg/kg | 5000mg/kg single dose, 14days Observation, OECD TG420(2001) conformity |

| Primary skin irritation test (Rabbit) |

(Primary irritating index) 0<Nonstimulating> |

OECD TG404(2015) ISO10993-10:2010 conformity |

||

| Agents for treatment of oral mucosa(Guinea pig) |

(Visual observation) Not particular |

Suspension 800mg/mL 4times/day×Straight for four days |

CIM Apatite feedstock (Compound material for ceramic injection molding)

|

Mixed by Nishimura’s unique CIM binder with Apatite powder. Only thermal debinding is needed, no liquid/chemical debinding. |