Compare with conventional product Compare with conventional product |

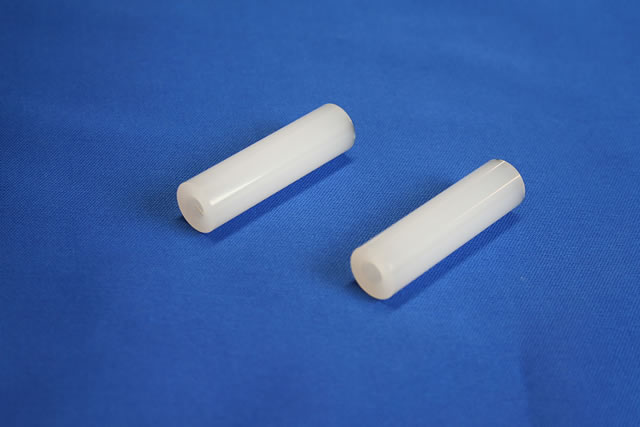

N-9000NS tube N-9000NS tube15mm outer dia.×6mm inner dia.×56mm |

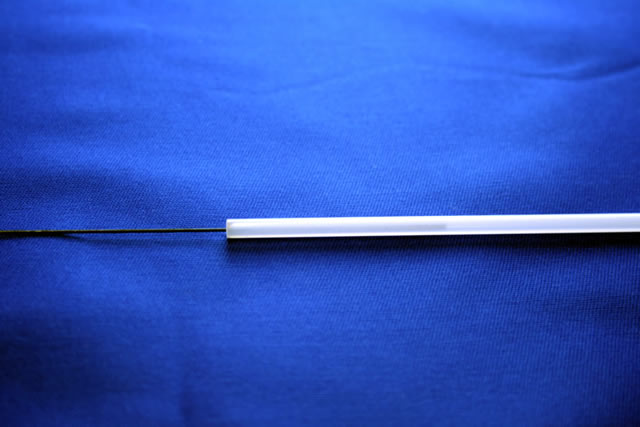

N-9000NS tube N-9000NS tube4mm outer dia.×2mm inner dia.×170mm |

|

N-9000NS Complex Box Shape |

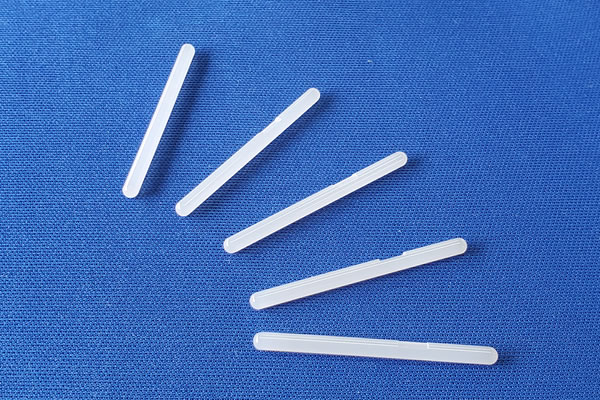

N-9000NS Wafer Lift Pins N-9000NS Wafer Lift Pins |

N-9000NS

Ceramic Parts Hong Kong produce Translucent Alumina Ceramics with high-intensity. It has high total light transmittance.

Ceramic Parts Hong Kong produce Translucent Alumina Ceramics with high-intensity. It has high total light transmittance.

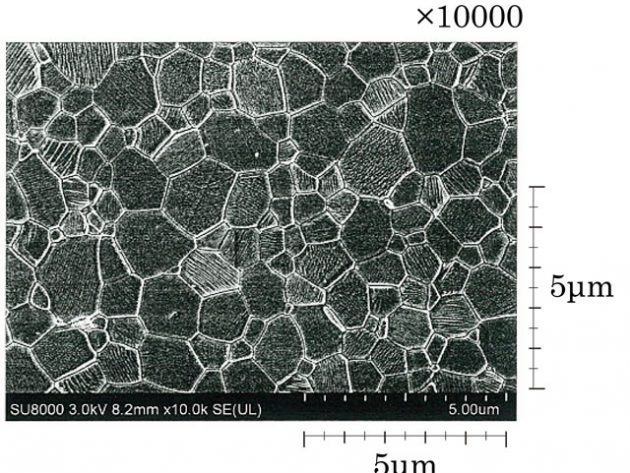

As N-9000NS is produced from pure fine-grain Alumina, it has a higher intensity than other translucent aluminas.

It can also be used as a substitute material for sapphires for its high intensity.

Characteristics

| Material | Alumina | Sapphire | ||

| Nishimura Ref. NO | N-9000NS | ━ | ||

| Component (Al2O3) |

>99.99% |

99.99% | ||

| Color | Translucency | ━ | ||

| Density | g/cm3 | 3.99 | ━ | |

| Water Absorption | % | 0 | ━ | |

|

Mechanical Properties |

Vickers Hardness | GPa | 21.4 | Similar |

| Bending Strength | MPa | 820 | Weaker | |

| Compressive Strength | MPa | 5800 | Weaker | |

| Tensile Strength | MPa | 213 | ━ | |

| Impact Strength | MPa | 0.7 | ━ | |

| Electrical Properties | Volume Resistivity | Ω・cm |

2.0×1016(20~100℃) |

━ |

| Permittivity | 1MHz | 10 | ━ | |

|

Dielectric Loss Tangent |

1MHz |

<0.001 |

━ | |

| Dielectric Strength | kV/mm | >10 | ━ | |

| Te Value | ℃ | 1000 | ━ | |

| Thermal Properties | Thermal Expansion Coefficient | 10-6/℃ | 8.2 | ━ |

| Heat Thermal Conductivity | W/m・K | 37 | ━ | |

| Max Operation Temperature | ℃ | 1200 | ━ | |

| Thermal Shock Resistance | ℃ | 200 | ━ | |

Features

- more competitive price than crystal sapphire (In the case of complex shape or bar shape)

- High intensity

- It can be produced by green machining method / CIM / Mold press.

- Smaller crystals compared to translucent alumina or transparent alumina ceramics.

- N-9000NS has great smooth surface. (Ra)

- N-9000NS can be used as substitute of single crystal sapphires

Applications

- Parts of semiconductor devices

- Alternative material of Sapphire

- Substrates for electric parts

- Heat-resistant and Corrosion-resistant material. E.g. Reaction tube, crucible

- Medical equipments and analyzers

- RF Window

N-9000 characteristics table(PDF)