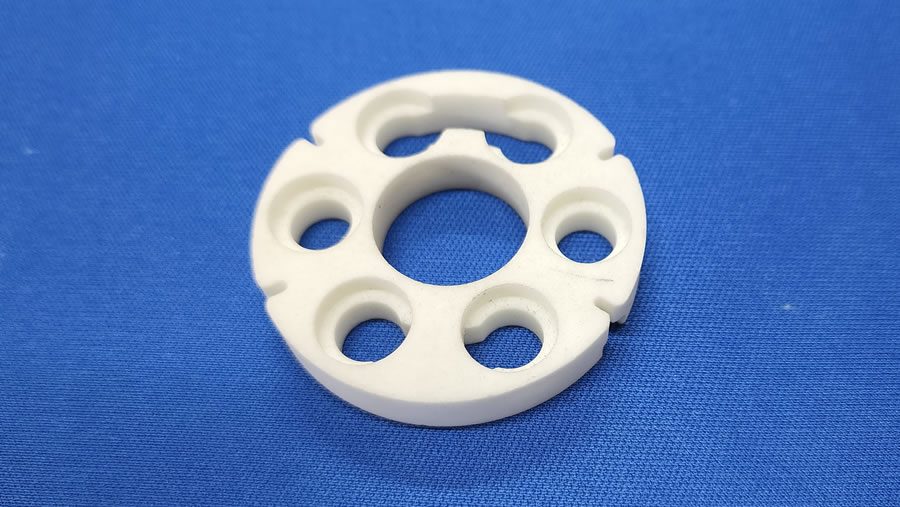

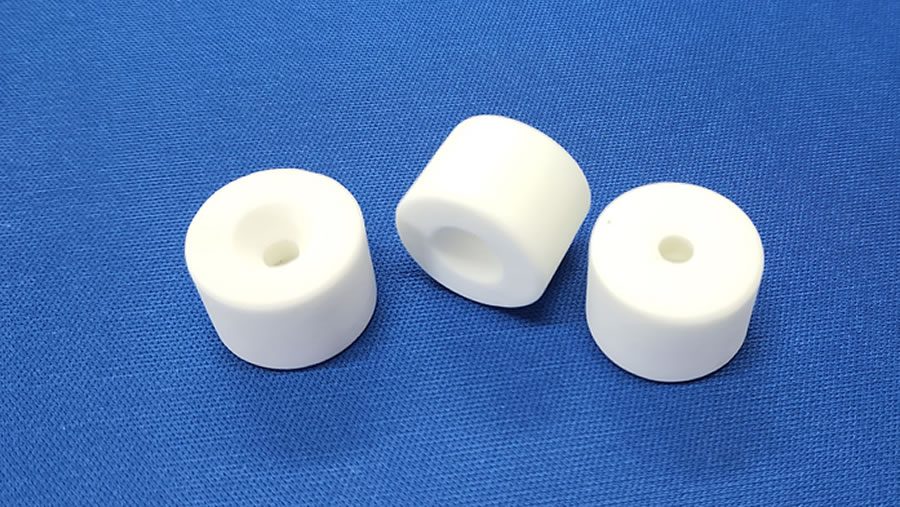

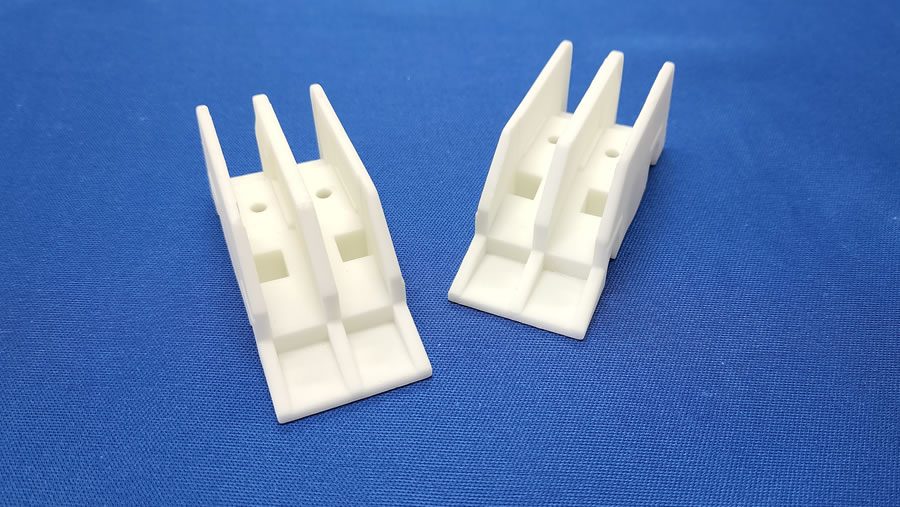

This is the most cost-effective method of producing ceramics with complex shapes. Tiny bubbles may be inherent.

Nishimura Ceramics has over 30 years of experience in manufacturing and selling low-pressure injection molded products.

|

|

|

|

|

| Low-pressure Injection | High-pressure Injection | Hydraulic Press | Green Processing | Sintered body processing | |

| Cost-efficiency Per Unit | ◎ | ◎ | ◎ | 〇 | ▽ |

| Cost-efficiency Per Mold | 〇 | ▽ | △ | ◎ | ◎ |

| Formability | 〇(thickness~4mm) | 〇(thickness~3mm) | ▽ | 〇 | ◎ |

| Mold Lead Time | 〇 | ▽ | △ | ◎ | ◎ |

| Texture Controllability | ▽ | 〇 | ◎ | ◎ | ◎ |

| Size Support | △ | ▽ | 〇 | ◎ | ◎ |

| Dimensional precision | △ | 〇 | 〇 | ◎ | ◎ |

Supported materials:

Alumina 99%, Steatite

Usage

Used in a wide variety of applications. There are concerns about its use as an insulating parts for high voltage.